Quick Summary

Replacement spa pumps often do not ship with a power leads, as every spa pack is wired differently. To reuse the cable from your old pump you will: (1) photograph the original installation, (2) note the wire colours and terminal locations, (3) remove the cable from the old motor, and (4) refit it to the new one while following the colour-code charts for either UK or US wiring. Always isolate the supply, use appropriate tools and, if in doubt, hire a qualified electrician.

Why no Cable is Supplied

Replacement pumps are sold "bare" because the original spa manufacturer sets the wiring to match its own control pack, normally via a moulded JJ or AMP plug on the power lead. Reusing that cable ensures the new pump remain plug-and-play with your spa pack.

Safety First

- Isolate the Supply - turn off the breaker and confirm with a meter that no voltage is present.

- Work in a dry environment - water and electricity are a lethal combination.

- Use an RCD on the pump circuit where possible.

- If you are unsure, stop and consult a qualified electrician; UK regulations (BS 7671) require competent workmanship on fixed wiring.

Wiring Colour Codes

UK single phase

- Brown - Live (Low Speed)

- Black - Live 2 (High Speed, 4 core only)

- Blue - Neutral

- Green/Yellow - Earth (protective conductor)

USA Convention (UL 62)

- Black - Live (Low Speed)

- Red - Live 2 (High Speed)

- White - Neutral

- Green - Earth/Ground

Installing the Lead on the New Pump

- Remove the new motor's terminal-box lid and review the wiring diagram inside.

- feed the existing cable through the gland and place each terminal onto the matching post, keeping the washer order unchanged.

- Tighten each nut finger-tight, then nip another quarter-turn with a spanner - do not overtighten.

- Secure the gland so the cable cannot twist or pull out.

- Refit the lid, connect plumbing and restore power.

First Power Checks

- Pump should start on its programmed speed with no tripping.

- If the motor hums and stops, check supply voltage, terminal tightness, and that HS/LS are not swapped.

- Persistent issues: isolate and consul an electrician or the pump manufacturer's troubleshooting guide.

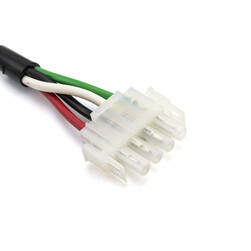

Damaged Cables

Pre-wired leads and connectors - Hydrospares stocks JJ and AMP cables for three- and four-core applications in various sizes, offering a compatible replacement for a system where the original cable is unable to be used.